What is Filament Winding?

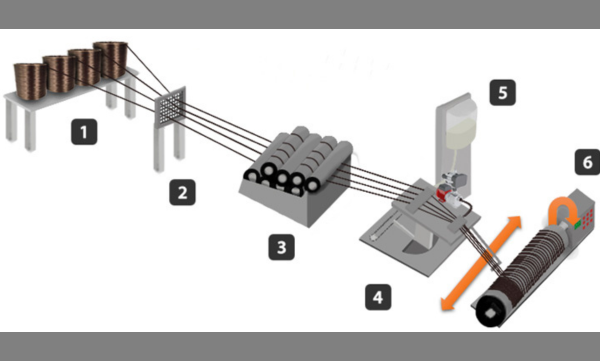

Filament winding is a technique primarily used to manufacture hollow, circular, or prismatic parts such as pipes and tanks. It is performed by winding continuous fiber tows onto a rotating mandrel using a specialized winding machine

It is a suitable production method for composites such as tanks, silos, ducts, water tanks, pipes and pressurized vessels over a suitable designed mandrel. Orsons resin are an ideal choice with high mechanical strength, chemical resistance and good fiber dispersibility for this purpose.

Process : In filament winding a filamentous yarn or tow is first wetted by a resin and then uniformly and regularly wound around a rotating mandrel along a pre described path. Also pre-impregnated tapes can be used at a an alternative. After the wound stage, the composite is curved by heating at a given temperature in an over or autoclave or by exposure to IR radiation, and the mandrel is removed. Typical products range from a simple pipe to an aircraft fuselage, while typical materials include glass, carbon or aramid fibers coupled to polyester, vinyl ester or epoxy resin.

We offer wide range of Filament winding resins like a.Orthophthalic resin for Filament winding, b.Isophthalic Resin for Filament winding, c.terephthalic resin, d.Vinyl ester resin suitable for all kind of Filament winding application.

Following are the properties offered by our resins :

- Excellent stiffness

- Chemical resistance

- Excellent wet out

- Batch to batch consistency

To know more about Resins for Filament Winding applications, Please feel free to connect with Orson Resins on sales@orcpl.com