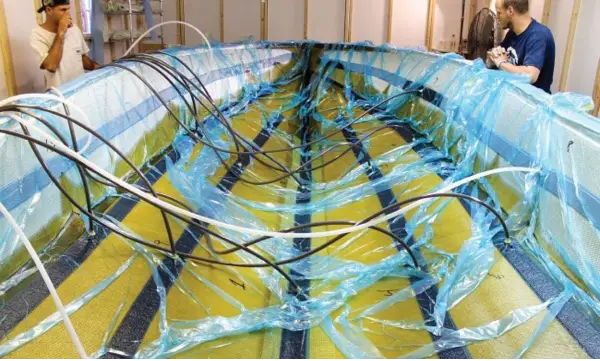

Resin Infusion is a process by which a vacuum draws resin into a dry fibre laminate in a one-sided mould. A rigid or flexible film membrane is placed over the top and sealed around the mould periphery. Resin infusion is considered a “Closed Mold Process”.

Resin choice is another key aspect.

“Infusion resin” is required for infusion, though there are some general guidelines that should be considered when making a decision. One important piece of information that should be examined is the resin viscosity. Vinyl Ester is the most frequently used resin for vacuum infusion.

Vinyl Ester is the most frequently used resin for vacuum infusion. The resin manufactured by Orson can withstand chemicals and it will not react the same way that other materials will. The resin is flexible and will not crack or break when exposed to pressure.

Resin infusion, when done correctly, can produce parts of incredible strength and quality of appearance. The resin infusion process also eliminates some of the problems that can affect the quality of composites, such as air voids (caused where the reinforcement has bridged around tight corners and tiny air bubbles caused by air trapped within the laminate. Orson Resins and coatings provide accurate resin required for the Infusion process. Be sure to contact Orson Resins and Coatings today for more information on Resins used for the Infusion process.